250KVA Three Phase step-up transformer

Cat:Three Phase transformer

A three-phase step-up transformer is an electrical device used to convert low-voltage three-phase alternating current to high-voltage three-phase alte...

See Details

In today's complex and ever-changing power systems, a stable power supply environment is the cornerstone for ensuring efficient and reliable operation of various electrical equipment. However, the voltage in the power grid is not static, and continuous voltage fluctuations often occur. Among them, the slow rise and fall of voltage due to load changes is a common situation. At this time, the three-phase AC output reactor stepped forward and took on the important task of stabilizing the voltage, becoming an indispensable key equipment in the power system.

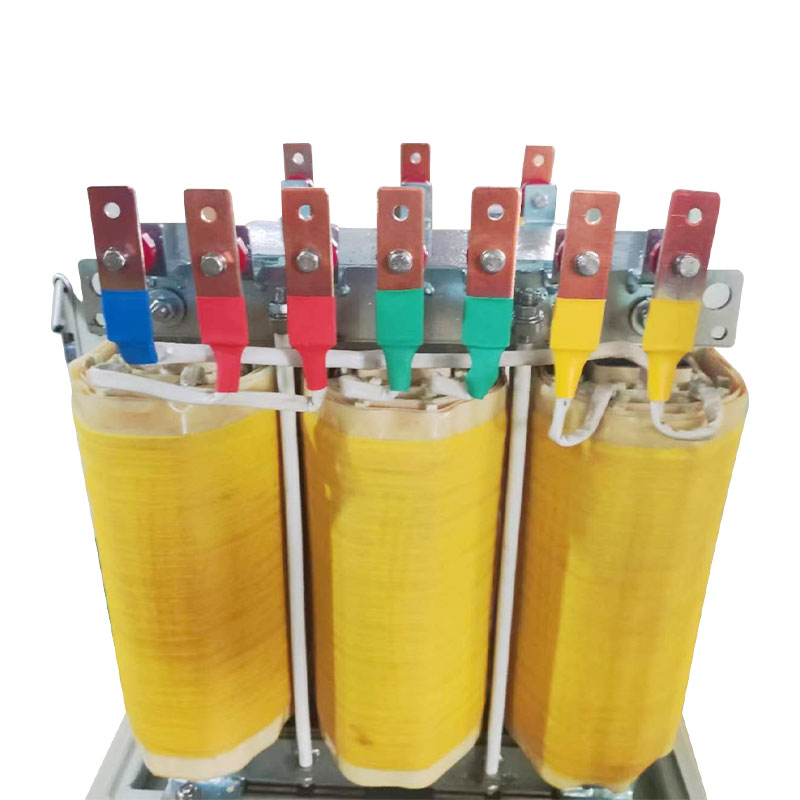

The three-phase AC output reactor is mainly composed of two core parts: the iron core and the winding. The iron core is generally made of high-permeability silicon steel sheets carefully stacked. This structural design can guide and concentrate the magnetic flux to a great extent, effectively reduce hysteresis and eddy current losses, and lay the foundation for the efficient operation of the reactor. The winding is wound on the iron core with copper or aluminum wires of suitable specifications according to different application scenarios and complex electrical parameter requirements. Its working principle is closely based on the law of electromagnetic induction. When the AC current continuously passes through the reactor winding, it will induce alternating magnetic flux in the iron core, and this magnetic flux will in turn induce electromotive force in the winding. According to Lenz's law, the direction of the induced electromotive force is always opposite to the trend of the original current change. It is this characteristic that constitutes the core theoretical basis for the reactor to cope with voltage fluctuations.

When the power grid produces continuous voltage fluctuations due to load changes, the three-phase AC output reactor quickly intervenes and plays a key regulatory role. As the grid voltage slowly rises and falls, the current in the reactor winding will also change accordingly. The change in current is like a stone thrown into a calm lake, breaking the original balance and causing dynamic changes in the magnetic flux in the iron core. The change in magnetic flux prompts the reactor winding to induce electromotive force. This induced electromotive force is like a well-trained "regulation master" to continuously compensate or weaken the voltage fluctuation. It will automatically adjust its size and direction according to the specific situation of the voltage fluctuation, and cleverly cooperate with the grid voltage, so as to steadily maintain the motor terminal voltage at a relatively stable level. This dynamic adjustment process is not achieved overnight, but like a tireless guard, it monitors the changes in grid voltage in real time and responds quickly and accurately to ensure that the motor always works in a suitable voltage environment, just like creating a "safe haven" for the motor that is free from voltage fluctuations.

From the perspective of actual application scenarios, in the field of industrial production, the frequent start and stop of many large-scale production equipment and the dynamic changes in loads can easily cause continuous fluctuations in grid voltage. For example, in the steel smelting process, when large equipment such as arc furnaces are working, their power demand will change greatly with the different smelting stages, which will inevitably lead to frequent and obvious fluctuations in grid voltage. If there is no effective adjustment of the three-phase AC output reactor at this time, various types of equipment driven by the motor, such as fans and water pumps, will be difficult to operate stably. The instability of the fan speed will affect the ventilation effect in the furnace, thereby interfering with the chemical reaction of the smelting process; the fluctuation of the water pump flow may cause the cooling system to work abnormally, threatening the safety of the equipment. The application of three-phase AC output reactors can effectively stabilize the motor terminal voltage, ensure the stable operation of these equipment, ensure the smooth progress of the steel smelting process, and improve production efficiency and product quality.

In commercial buildings, large equipment such as central air-conditioning systems and elevators are also "large loads" of the power grid. When the central air-conditioning system switches between cooling or heating modes and the load in different areas changes, it will draw currents of different sizes from the power grid, causing voltage fluctuations. The frequent up and down movement of elevators, and the alternation between full load and no-load, will also affect the voltage of the power grid. If these voltage fluctuations are not controlled, they will not only affect the cooling and heating effects of the air-conditioning system, resulting in reduced indoor comfort, but may also cause a sense of frustration in the operation of the elevator, affecting the passenger experience and even endangering safety. The installation of three-phase AC output reactors can effectively buffer and regulate these continuous voltage fluctuations, ensure the smooth operation of various electrical equipment in commercial buildings, and improve the overall operation level of the building.

In dealing with continuous voltage fluctuations caused by load changes in the power grid, the three-phase AC output reactor has demonstrated excellent regulation performance with its ingenious structural design and exquisite working principle. It provides a stable voltage environment for electrical equipment such as motors, and plays an irreplaceable and important role in many fields such as industrial production and commercial buildings. In today's pursuit of stable and efficient operation of power systems, in-depth understanding and rational application of three-phase AC output reactors have far-reaching significance for ensuring the reliable operation of electrical equipment and improving the performance of the entire electric drive system. It deserves the attention and in-depth research of power engineers, equipment operation and maintenance personnel, and related industry practitioners.

Contact Us