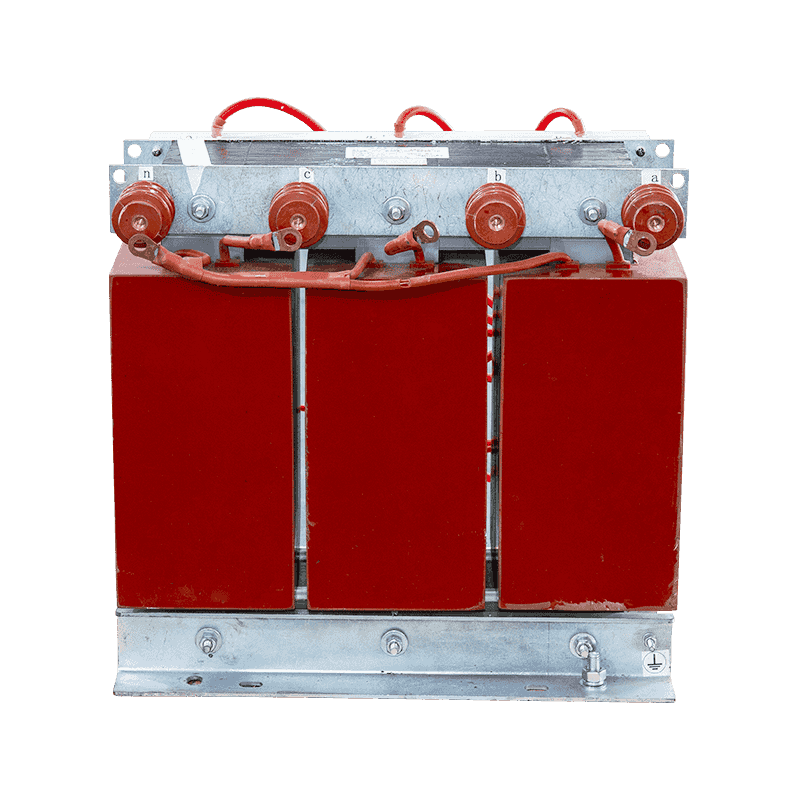

20 KVA Epoxy resin Three Phase Dry type transformer

Cat:Three Phase transformer

Epoxy resin three-phase dry-type transformerFeatures:1. Improve insulation strength and electrical resistanceEpoxy resin is a great electrical insulat...

See Details

The demand for efficient, safe, and environmentally friendly power distribution solutions has grown significantly in industrial and commercial sectors. Among the various options available, the 20 kVA epoxy resin three-phase dry-type transformer has emerged as a leading choice due to its reliability, durability, and compliance with modern energy standards. Unlike traditional oil-filled transformers, this type of unit eliminates the risks of leaks, reduces maintenance requirements, and offers superior thermal performance.

Epoxy resin encapsulation is a defining feature of modern dry-type transformers, particularly in the 20 kVA three-phase category. This material provides exceptional insulation and structural integrity, making the transformer highly resistant to environmental and operational stresses.

One of the primary benefits of epoxy resin is its flame-retardant properties. Unlike oil-cooled transformers, which pose fire hazards due to combustible insulating fluids, epoxy resin does not support combustion. This makes the 20 kVA epoxy resin transformer suitable for installations in high-risk environments such as chemical plants, mines, and densely populated commercial buildings.

Additionally, epoxy resin offers excellent moisture and dust resistance. Since the windings are fully encapsulated, the transformer remains unaffected by humidity, corrosive gases, or airborne contaminants. This ensures long-term reliability even in harsh industrial settings. The material also provides superior thermal conductivity, allowing efficient heat dissipation without the need for liquid cooling systems.

Another advantage is mechanical strength. The epoxy resin solidifies into a rigid structure that protects the internal components from vibrations and short-circuit forces. This is particularly important in heavy industrial applications where mechanical stress is a concern.

Compared to cast resin transformers (a similar category), the 20 kVA epoxy resin three-phase dry-type transformer offers a balanced combination of performance and cost-effectiveness. While both types use resin for insulation, epoxy-based units typically provide better resistance to thermal cycling and partial discharge, extending operational lifespan.

Three-phase power distribution is the backbone of industrial and large-scale commercial operations. The 20 kVA three-phase dry-type transformer is specifically engineered to meet the demands of high-load environments, ensuring stable and efficient electricity delivery.

One of the key advantages of a three-phase system is its ability to deliver balanced power. Unlike single-phase transformers, which can cause uneven load distribution, three-phase units provide consistent voltage levels across all phases. This is crucial for machinery, motors, and data centers where voltage fluctuations can lead to equipment failure or inefficiency.

The 20 kVA rating is particularly well-suited for medium-power applications. It can efficiently support:

| Application | Typical Use Case |

|---|---|

| Manufacturing Plants | Powering CNC machines, conveyor systems |

| Data Centers | Backup power distribution |

| Hospitals & Laboratories | Critical medical equipment |

| Commercial Buildings | HVAC systems, lighting networks |

Another benefit of the three-phase dry-type transformer is its compact design. Since three-phase systems transmit more power with less conductor material compared to single-phase alternatives, they occupy less space while delivering higher efficiency. This makes them ideal for facilities with limited installation areas.

Additionally, modern dry-type transformers often incorporate energy-efficient core materials such as amorphous metal or high-grade silicon steel. These materials reduce no-load losses, contributing to lower operational costs over time.

Environmental regulations and corporate sustainability goals have driven the adoption of dry-type transformers over traditional oil-filled models. The 20 kVA epoxy resin three-phase dry-type transformer aligns with these trends by eliminating hazardous materials and reducing energy waste.

A major environmental benefit is the absence of insulating oil. Oil-filled transformers require periodic maintenance and pose contamination risks in case of leaks. In contrast, dry-type transformers use solid insulation (epoxy resin), removing the risk of soil or water pollution. This makes them compliant with EPA and RoHS regulations, which restrict the use of hazardous substances in electrical equipment.

Furthermore, dry-type transformers have a lower carbon footprint over their lifecycle. Since they do not rely on oil cooling, there is no need for oil containment systems or spill prevention measures. Their higher thermal efficiency also reduces energy losses, contributing to lower greenhouse gas emissions.

From a regulatory standpoint, epoxy resin transformers meet international standards such as:

These certifications ensure that the 20 kVA epoxy resin three-phase dry-type transformer can be deployed in global markets without compliance concerns.

Choosing the right transformer involves evaluating several technical and operational factors. The 20 kVA epoxy resin three-phase dry-type transformer offers numerous advantages, but proper selection ensures optimal performance and cost efficiency.

The 20 kVA rating is suitable for medium-power applications, but future expansion should be considered. If load demand is expected to increase, selecting a slightly higher-rated transformer (e.g., 25 kVA) may be more economical in the long run.

Dry-type transformers typically use two cooling methods:

For most 20 kVA applications, AN cooling is sufficient, but AF may be necessary in high-ambient-temperature settings.

Since epoxy resin transformers are resistant to moisture and dust, they can be installed in challenging locations. However, proper ventilation should still be maintained to prevent overheating.

Modern facilities increasingly adopt IoT-enabled transformers for real-time condition monitoring. Some dry-type transformers support integrated sensors for temperature, load, and insulation health tracking.

While dry-type transformers have a higher upfront cost than oil-filled units, their lower maintenance and longer lifespan often result in better long-term value.

The 20 kVA epoxy resin three-phase dry-type transformer represents a modern, efficient, and sustainable solution for industrial and commercial power distribution. Its epoxy resin insulation ensures safety and durability, while the three-phase design delivers balanced and reliable performance. Additionally, its compliance with environmental regulations makes it an ideal choice for businesses aiming to reduce their ecological impact.

When selecting a transformer, factors such as load capacity, cooling method, and smart monitoring capabilities should be carefully evaluated. By choosing the right dry-type transformer, organizations can achieve energy efficiency, operational reliability, and long-term cost savings.

As industries continue to prioritize safety and sustainability, the 20 kVA epoxy resin three-phase dry-type transformer is poised to remain a cornerstone of modern electrical infrastructure.

Contact Us