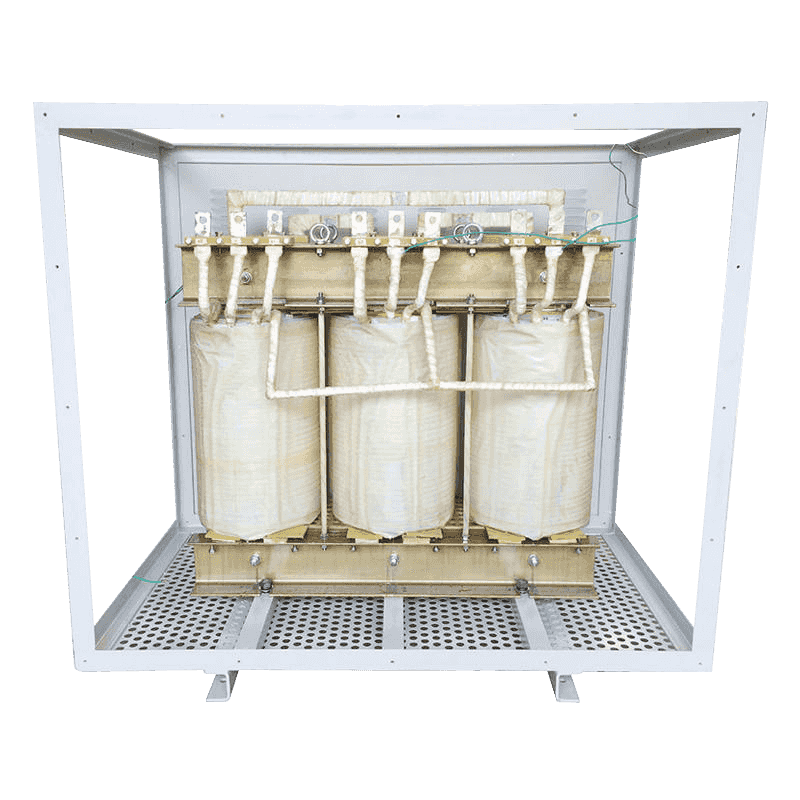

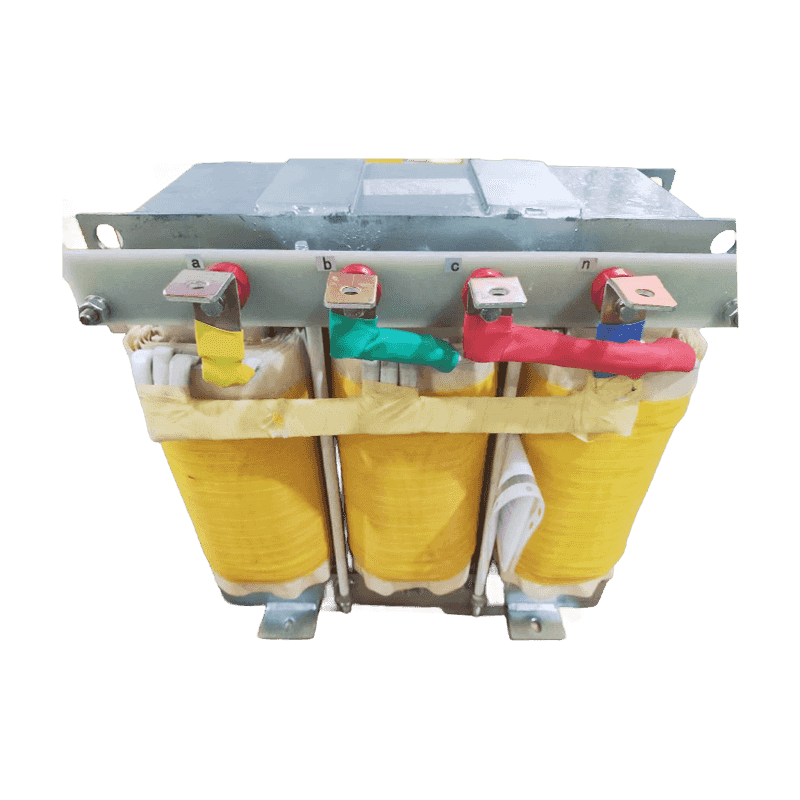

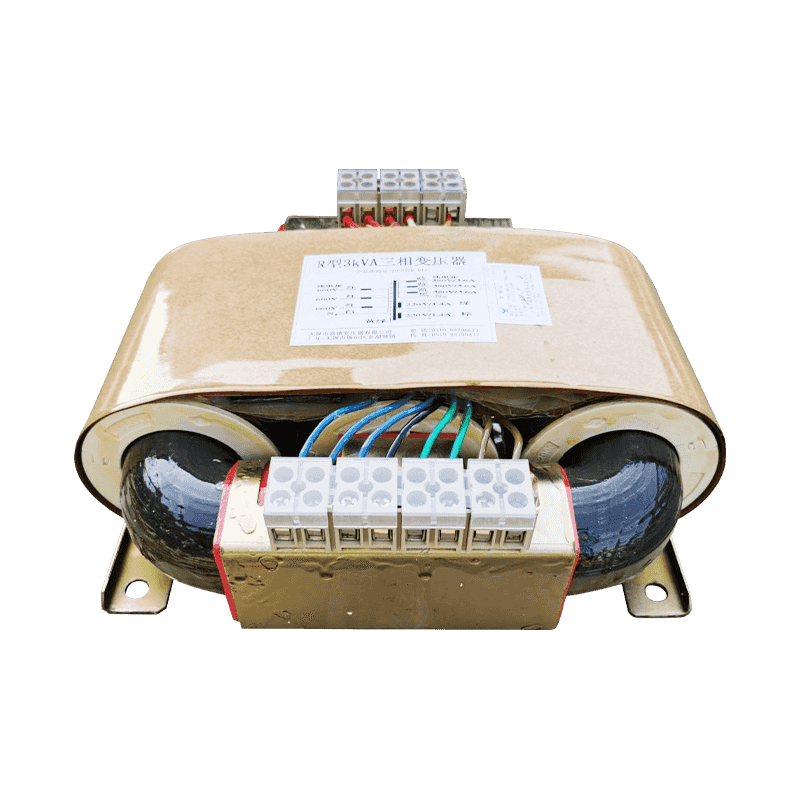

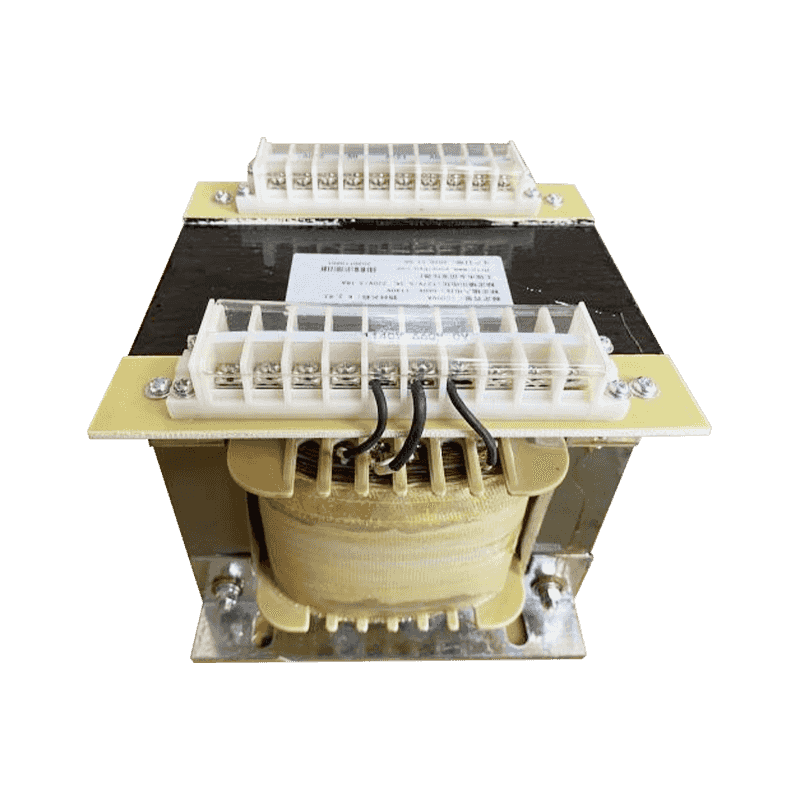

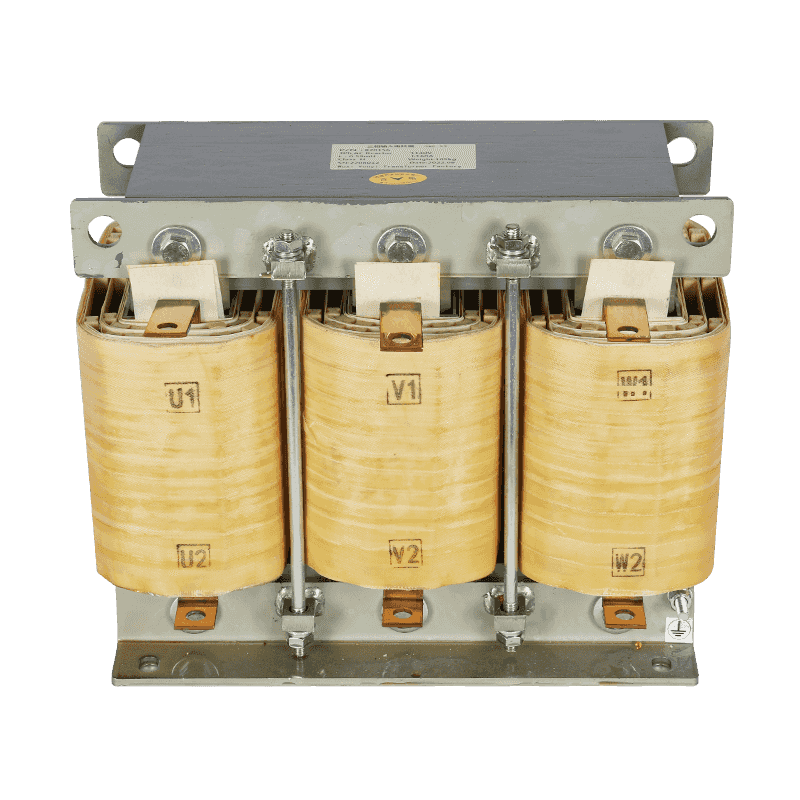

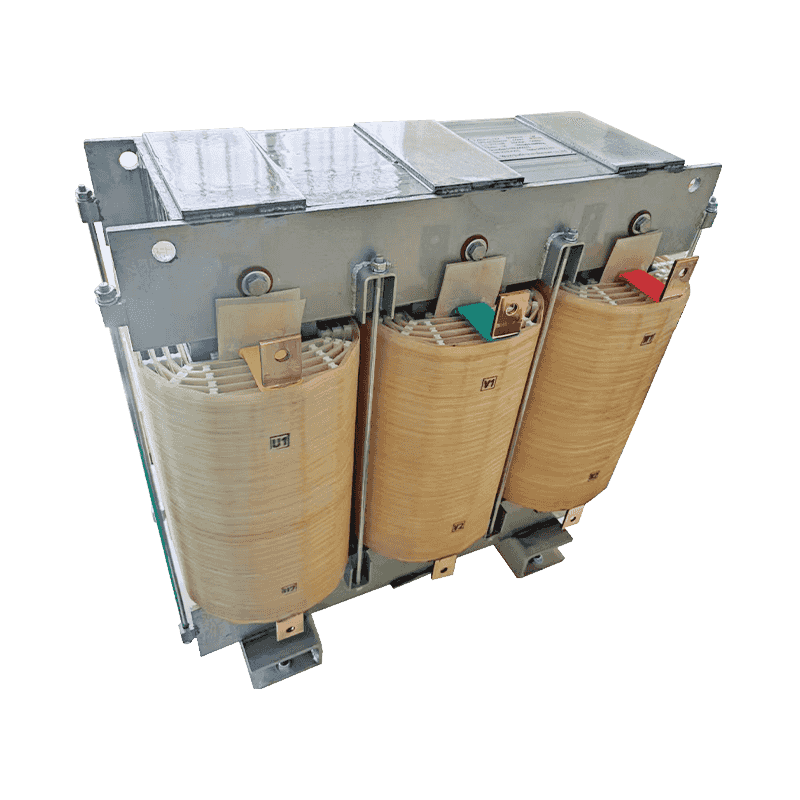

In the power system, the 250KVA copper wire 3300V to 480V three-phase transformer is the core equipment for power conversion, and its operating stability is closely related to its heat dissipation capacity. Especially under rated load or even overload conditions, effective control of winding temperature becomes the key to ensure the continuous and reliable operation of the transformer, and the vacuum varnishing process plays an irreplaceable role in improving the heat dissipation performance of the transformer.

During the operation of the 250KVA three-phase transformer, the copper loss of the winding and the iron loss of the core will continue to generate heat. If this heat cannot be dissipated in time, the winding temperature will continue to rise, which will not only accelerate the aging of the insulation material, but may also cause serious faults such as insulation breakdown, threatening the safety and stability of the power system. Therefore, building an efficient heat dissipation system is the top priority in the design and manufacture of such transformers.

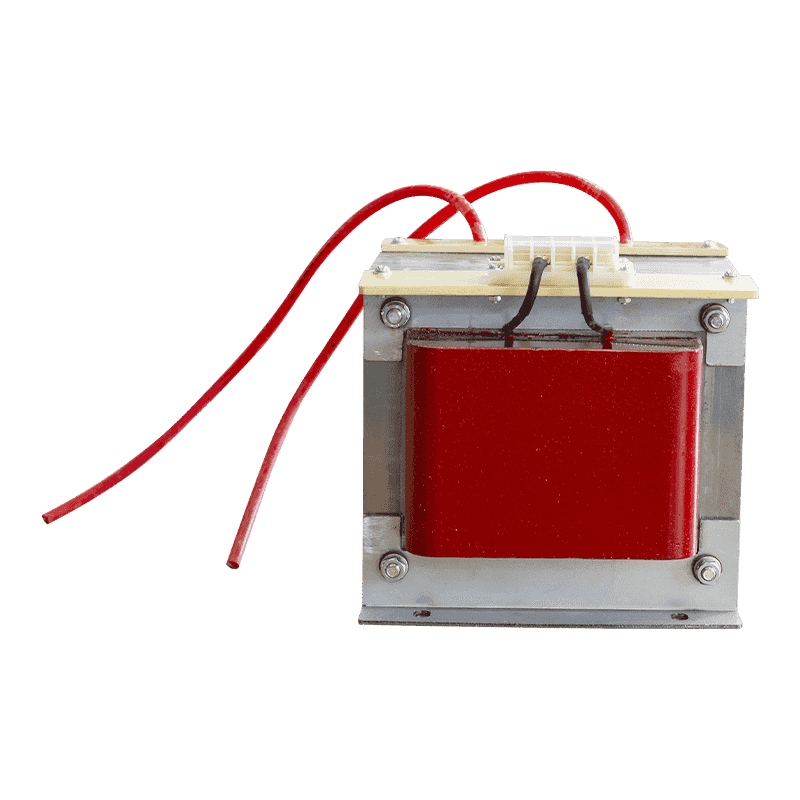

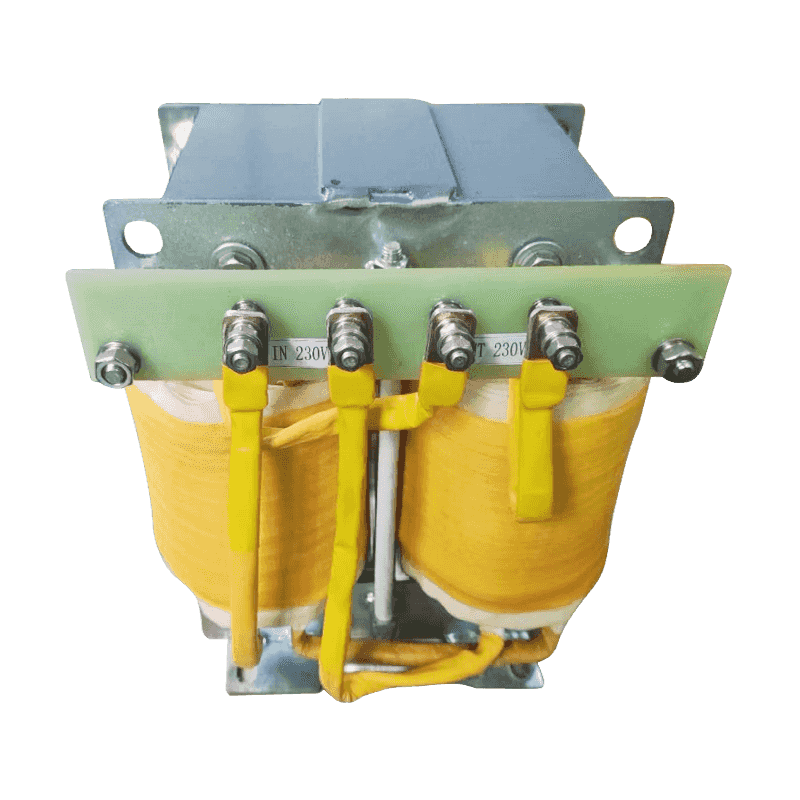

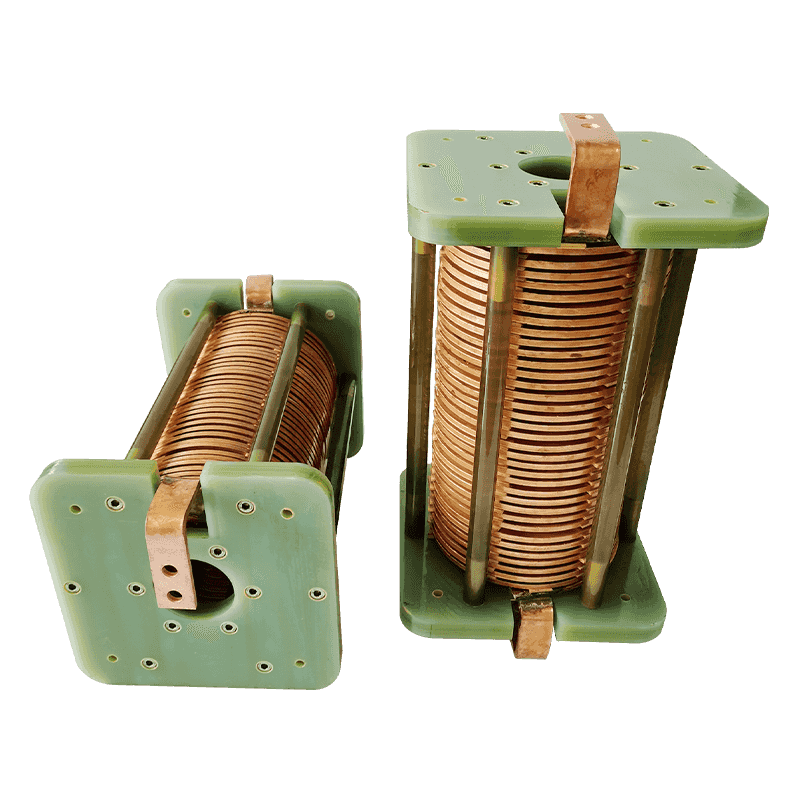

The application of vacuum varnishing technology has opened up a new path for improving the heat dissipation performance of transformers. This process places the transformer winding in a vacuum environment, uses negative pressure to completely remove air and moisture inside the winding, and eliminates the air gap that hinders heat conduction. Subsequently, the insulating varnish relies on gravity and capillary effect in a vacuum environment to evenly penetrate every gap and micropore of the winding to form a dense insulating layer. This insulating layer not only has excellent electrical insulation performance, but its good thermal conductivity significantly enhances the heat dissipation capacity of the transformer.

In a 250KVA copper wire 3300V to 480V three-phase vacuum impregnation transformer, the insulating layer formed by vacuum impregnation is like an efficient heat conduction channel. It quickly transfers the heat generated by the winding to the transformer casing, and then dissipates it to the surrounding environment through air convection or cooling devices. Compared with the traditional impregnation process, the insulating layer formed by vacuum impregnation fits tightly with the winding, reduces thermal resistance, and greatly improves the heat transfer efficiency. This enables the transformer to always control the winding temperature within a reasonable range when operating at rated load, avoiding performance degradation due to excessive temperature.

In the face of overload conditions, the heat dissipation advantage of vacuum impregnation transformers is more prominent. When the load increases and the heat generated by the winding rises sharply, the efficient heat dissipation system formed by vacuum impregnation can respond quickly. On the one hand, the good thermal conductivity of the insulating paint accelerates heat conduction; on the other hand, the structure formed by its tight wrapping of the winding optimizes the heat transfer path of the winding, allowing the heat to diffuse rapidly. Under this dual effect, even in a short-term overload operation, the transformer can effectively control the winding temperature, avoid failures caused by overheating, and ensure the stability and continuity of the power conversion process.

In addition to directly enhancing the heat conduction capacity, the vacuum varnishing process also indirectly optimizes the heat dissipation effect by improving the overall performance of the transformer. The solid insulation layer formed after varnishing enhances the mechanical strength of the winding, making the winding more stable during operation and reducing heat conduction losses caused by factors such as vibration. At the same time, the good sealing of the insulation layer isolates the intrusion of external impurities such as moisture and dust, prevents the accumulation of impurities from affecting the heat dissipation effect, and further ensures the long-term stable operation of the transformer heat dissipation system.

The 250KVA copper wire 3300V to 480V three-phase vacuum varnishing transformer builds an efficient heat dissipation system with the vacuum varnishing process. From eliminating air gaps and enhancing heat conduction to optimizing heat transfer paths and improving overall performance, the vacuum varnishing process fully guarantees the heat dissipation requirements of the transformer under rated load and overload conditions, ensuring its continuous and stable operation in the power system, and providing solid protection for the reliability and safety of power supply.

Eng

Eng  Español

Español

Contact Us