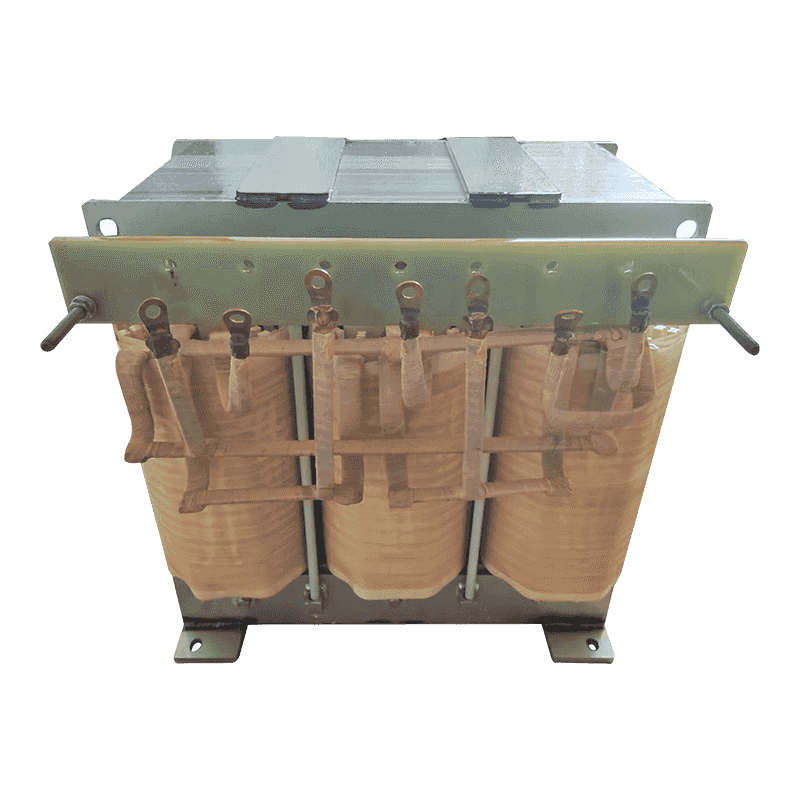

30KVA AL wire 230V to 480V 3PH Dry-type Transformer

Cat:Three Phase transformer

A three-phase transformer is a type of power transformer used to convert voltage from one three-phase circuit to another. They are widely used in powe...

See Details

In the core structure of 30KVA aluminum wire 230V to 480V three-phase dry-type transformers, epoxy resin, as a key insulating filling material, deeply affects the performance and service life of the transformer. This dry-type transformer uses air cooling medium. During the voltage conversion process of its aluminum wire winding, there is a complex electric field distribution between components with different potentials. The intervention of epoxy resin is the core technical solution to meet this challenge.

From the perspective of insulation mechanism, epoxy resin exhibits excellent electrical insulation performance due to its unique molecular structure. When not cured, the molecular chain segments of epoxy resin are linear or branched, with weak intermolecular forces and good fluidity. They can fully penetrate into the tiny gaps of transformer windings and various components in the vacuum pressure impregnation (VPI) process to achieve seamless filling. After cross-linking reaction with the curing agent, the molecular chains are interconnected to form a three-dimensional network structure, and the electron migration path is greatly restricted, thereby significantly improving the breakdown voltage and volume resistivity of the material. This insulation property enables the transformer to effectively isolate components with different potentials during the voltage conversion process from 230V to 480V, prevent partial discharge and creepage, and ensure the stability and safety of power transmission.

The solid structure formed after the epoxy resin is cured not only has an insulating function, but also plays a key role in mechanical strengthening. Compared with copper wire windings, aluminum wire windings have relatively weaker mechanical toughness and are easily affected by electromagnetic forces, thermal stress and mechanical vibration during long-term operation. The high-strength characteristics of epoxy resin after curing are like a solid "armor", which tightly wraps and fixes the windings and components. It effectively suppresses the local deformation and displacement of the winding by evenly dispersing the mechanical stress to the entire structure, avoiding the wear of the insulation layer or loosening of the wire due to vibration, thereby improving the fatigue resistance and mechanical stability of the transformer under complex working conditions. This structural strengthening effect ensures that the transformer can maintain long-term stability of electrical performance in dynamic operating scenarios such as frequent start-stop and load fluctuations.

In terms of thermal management, epoxy resin also plays an indispensable role. Dry-type transformers rely on air convection to dissipate heat, and the good thermal conductivity of epoxy resin can accelerate the diffusion of heat generated by the winding to the outside. Although its thermal conductivity is not as good as that of metal materials, by adding high thermal conductivity fillers such as alumina and boron nitride, it can effectively build an internal heat conduction channel, reduce the hot spot temperature, and avoid insulation aging caused by local overheating. At the same time, the low expansion coefficient of epoxy resin matches the aluminum wire winding. When the temperature changes, there will be no excessive stress between the two due to the difference in thermal expansion, which further ensures the integrity of the insulation structure.

In addition, the chemical stability of epoxy resin provides a guarantee for the long-term and reliable operation of the transformer. Its corrosion resistance enables it to resist corrosive media such as acid and alkali gases, humid water vapor, etc. commonly found in industrial environments, avoiding the degradation of insulation material performance. At the same time, epoxy resin also has good flame retardant properties. When encountering abnormally high temperatures or arc discharges, it can effectively suppress the spread of fire, reduce the risk of fire, and build a multiple safety protection system for the transformer.

Epoxy resin improves the overall performance of the 30KVA aluminum wire 230V to 480V three-phase dry-type transformer in all aspects through multi-dimensional synergy such as insulation performance optimization, mechanical structure reinforcement, thermal management improvement and chemical protection enhancement. The deep integration of this material and equipment structure not only ensures the efficiency and safety of the voltage conversion process, but also lays a solid foundation for the long-term stable operation of the equipment under complex working conditions.

Contact Us