30KVA AL wire 230V to 480V 3PH Dry-type Transformer

Cat:Three Phase transformer

A three-phase transformer is a type of power transformer used to convert voltage from one three-phase circuit to another. They are widely used in powe...

See Details

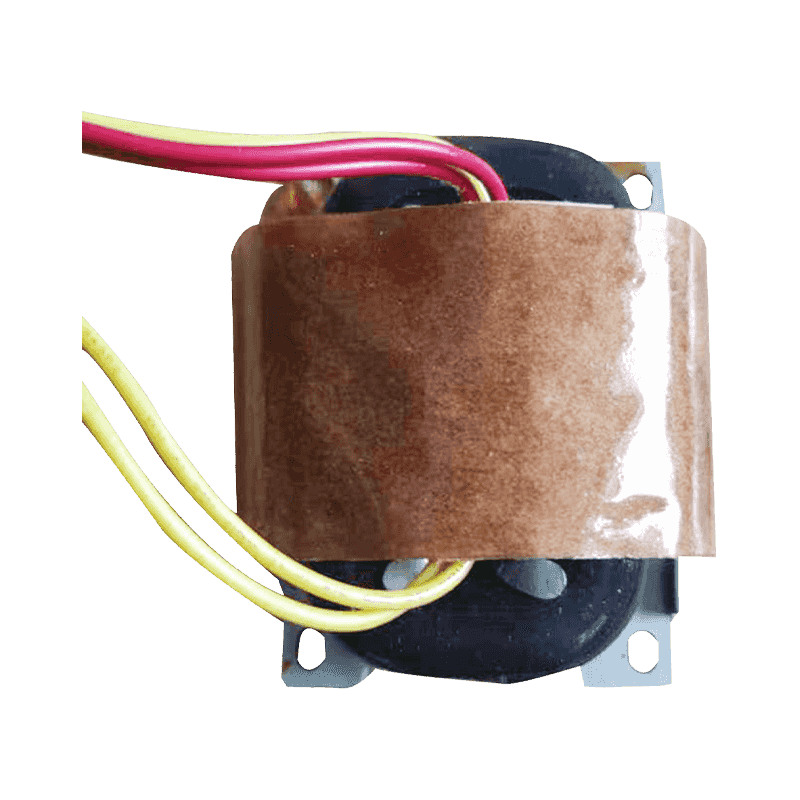

The R-type single-phase transformer is a specialized transformer design known for its compact structure, high efficiency, and reliable performance. One of its defining features is its unique winding configuration, which directly impacts its electrical characteristics, efficiency, and application suitability. Understanding the available winding configurations is crucial for engineers, technicians, and procurement specialists who need to select the right transformer for their specific needs.

Before delving into winding configurations, it is essential to understand the basic structure of an R-type single-phase transformer. Unlike traditional EI-core or toroidal transformers, the R-type design features a unique core shape that optimizes magnetic flux distribution. The windings are carefully arranged to minimize losses and improve thermal performance.

The primary and secondary windings are the key functional components, transferring electrical energy through electromagnetic induction. The way these windings are arranged—whether concentrically, side-by-side, or in other configurations—determines the transformer’s electrical behavior, including leakage inductance, voltage regulation, and efficiency.

The concentric winding arrangement is one of the most widely used designs in an R-type single-phase transformer. In this setup, the primary and secondary windings are wound concentrically around the core limb, with one winding placed inside the other. Typically, the low-voltage (LV) winding is wound closest to the core, while the high-voltage (HV) winding surrounds it.

Advantages:

Disadvantages:

This configuration is commonly used in power supplies, audio equipment, and industrial control systems where stable voltage output is critical.

In the sandwich winding arrangement, the primary and secondary windings are alternately layered, creating an interleaved structure. This design is particularly useful in applications requiring low leakage inductance and improved coupling efficiency.

Advantages:

Disadvantages:

This configuration is often found in high-performance electronics, medical devices, and precision instrumentation.

The disc winding design involves winding the conductor in flat, spiral-shaped discs stacked along the core limb. Each disc can function as either a primary or secondary winding segment, connected in series or parallel as needed.

Advantages:

Disadvantages:

This configuration is typically used in high-power industrial transformers and specialized electrical systems.

The helical winding method involves winding the conductor in a continuous spiral around the core, resembling a spring. This design is particularly effective for handling high currents while maintaining low resistance.

Advantages:

Disadvantages:

Helical windings are commonly used in welding machines, battery chargers, and low-voltage power distribution systems.

The following table summarizes the key differences between the winding configurations discussed:

| Winding Type | Best For | Advantages | Limitations |

|---|---|---|---|

| Concentric | General-purpose power supplies | Low leakage flux, compact design | Higher inter-winding capacitance |

| Sandwich (Interleaved) | High-frequency applications | Low leakage inductance, better cooling | Complex manufacturing |

| Disc | High-power industrial use | Mechanical stability, flexible tuning | Higher cost, insulation challenges |

| Helical | High-current, low-voltage systems | Low resistance, efficient cooling | Larger size, limited high-voltage use |

Choosing the right winding configuration for an R-type single-phase transformer depends on several factors:

Engineers must carefully evaluate these aspects to ensure optimal performance and reliability.

The winding configuration of an R-type single-phase transformer plays a critical role in determining its efficiency, thermal performance, and suitability for specific applications. Whether using concentric, sandwich, disc, or helical windings, each design offers distinct advantages and trade-offs.

By understanding these configurations, professionals can make informed decisions when selecting or designing transformers for various electrical and electronic systems. Future advancements in materials and manufacturing techniques may further refine these winding methods, enhancing the performance and versatility of R-type single-phase transformers.

Contact Us