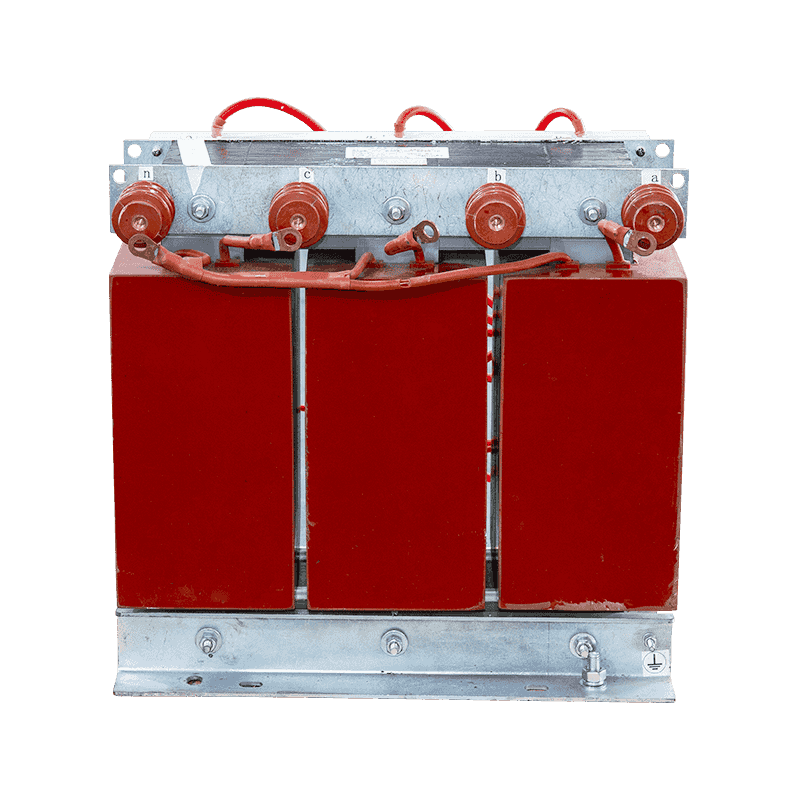

35KVA 208V to 380V Al wire 3PH Auto transformer

Cat:Three Phase transformer

An autotransformer is a special transformer in which the output and input share a common set of coils. Step-up and step-down are realized with differe...

See Details

In the field of power equipment, the 20 KVA epoxy resin three-phase dry-type transformer stands out for its excellent insulation performance, especially the extremely low partial discharge, which has become a key factor in ensuring the stable operation of the power system. Partial discharge is an important factor affecting the insulation life and operation reliability of the transformer. In the insulation structure of conventional transformers, due to uneven materials and the existence of air gaps, it is difficult to avoid local insulation weaknesses. Under the action of the electric field, these weak areas are very likely to cause partial discharge, but the 20 KVA epoxy resin three-phase dry-type transformer can effectively overcome this problem.

The low partial discharge characteristics of this transformer are due to its unique structural design and advanced manufacturing process. In the winding production process, the high and low voltage windings are wound with copper strips (foils). Compared with the traditional round wire winding method, copper strips (foils) can provide a more uniform electric field distribution. The smooth surface and regular shape reduce the electric field concentration points and reduce the possibility of partial discharge. At the same time, the copper tape (foil) winding process can also effectively control the dimensional accuracy of the winding, ensure the uniform distance between the windings, further optimize the electric field distribution, and inhibit the occurrence of partial discharge.

In the selection and application of insulating materials, epoxy resin plays a decisive role. Epoxy resin itself has good electrical insulation and adhesion. The process of pouring epoxy resin onto the winding in a vacuum and curing it is of great significance. The vacuum environment can exclude air and avoid the formation of air gaps in the insulation system. Air gaps are one of the common causes of partial discharge. Since the dielectric constant of gas is much lower than that of solid insulating materials, under the action of the electric field, the electric field strength in the air gap will be higher than that of the surrounding solid insulating materials, thereby inducing gas discharge. Through vacuum casting, the existence of air gaps is eliminated, and a continuous and uniform insulation barrier is built for the transformer, which greatly reduces the cause of partial discharge.

The cured epoxy resin is like a solid armor, tightly wrapping the winding, which not only provides reliable electrical insulation, but also enhances the mechanical properties of the transformer. Its dense molecular structure can effectively prevent the intrusion of impurities such as moisture and dust, and avoid electric field distortion and partial discharge caused by impurities. In addition, the chemical corrosion resistance of epoxy resin enables it to maintain stable insulation performance in the face of complex operating environments, preventing the degradation of insulation performance caused by chemical corrosion, and then causing partial discharge.

From the perspective of adaptability to the operating environment, the advantage of low partial discharge of the 20 KVA epoxy resin three-phase dry-type transformer enables it to operate stably under a variety of harsh working conditions. Whether in a high temperature environment, the heat resistance of the epoxy resin insulation system ensures that it will not produce air gaps or insulation degradation due to temperature increase, maintaining low partial discharge characteristics; or in a humid environment, the low permeability of epoxy resin effectively prevents the degradation of insulation performance and increased risk of partial discharge caused by moisture intrusion. This high adaptability to the environment ensures that the transformer always maintains extremely low partial discharge during long-term operation, extending the service life of the equipment and reducing maintenance costs.

The extremely low partial discharge of the 20 KVA epoxy resin three-phase dry-type transformer is an important guarantee for its wide application in urban power grids, high-rise buildings, hospitals, subways and other places with extremely high requirements for power reliability. Low partial discharge not only reduces the speed of insulation aging and the probability of equipment failure, but more importantly, it lays a solid foundation for the safe and stable operation of the power system, becoming an indispensable key equipment in the modern power field.

Contact Us