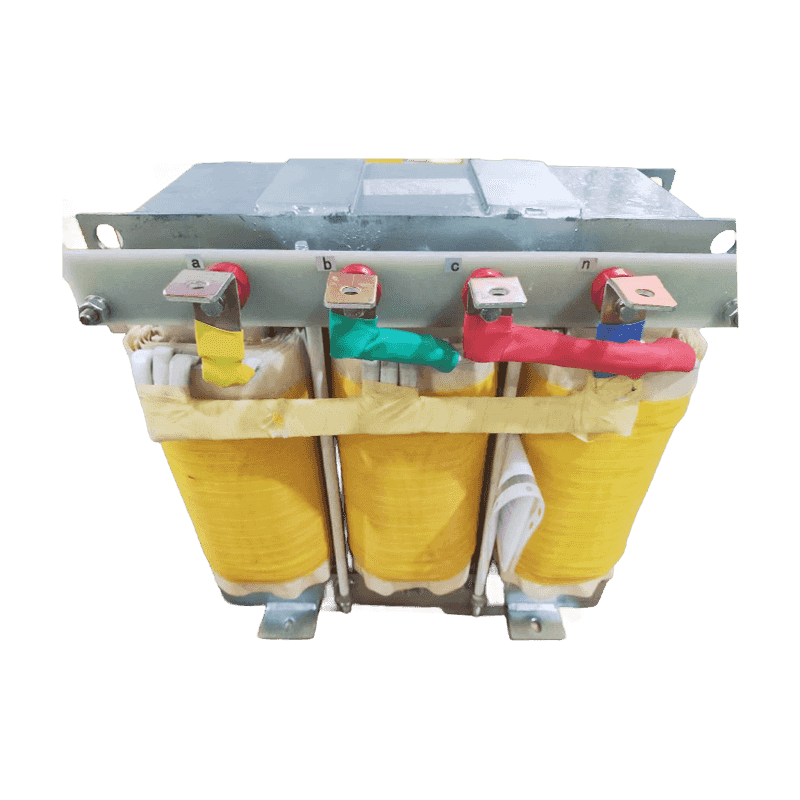

Three Phase step down transformer

Cat:Three Phase transformer

A three-phase step-down transformer is a common piece of electrical equipment used to reduce high voltages to scenarios where low load voltages are ap...

See Details

In the field of power transmission and distribution, the 350 KVA 400V to 140V aluminum wire three-phase isolation transformer plays a key role in achieving electrical isolation of input and output circuits with its unique winding design, and has become a core device to ensure the safe and stable operation of the power system.

The core of the electrical isolation function of this transformer lies in its winding structure design. The three-phase separated winding layout is adopted. The primary winding and the secondary winding of each phase are independent of each other, and there is no direct electrical connection between them, forming a physical isolation barrier. As a winding material, aluminum wire has good conductivity and economy, and is tightly wound on a high magnetic permeability iron core through a special winding process, which ensures efficient coupling of the magnetic field while strictly limiting the formation of electrical paths.

From the perspective of electromagnetic conversion principle, the transformer operates based on the law of electromagnetic induction. When the primary winding is connected to 400V three-phase AC, the alternating current generates a periodically changing magnetic field in the winding. The magnetic field forms a closed magnetic circuit through the iron core, and then induces 140V three-phase AC in the secondary winding. In this process, the energy transfer is completed only by magnetic field coupling, and the current cannot be directly conducted from the primary side to the secondary side, achieving electrical isolation. This isolation is not a simple physical disconnection, but while ensuring the efficient transmission of electric energy, it cuts off the potential current conduction path between the two circuits.

In terms of insulation design, the transformer adopts multi-layer composite insulation measures for the winding. The surface of the aluminum wire is covered with high-strength insulating paint, and the winding layers are filled with high-performance insulating materials such as polyester film and epoxy resin. At the same time, an insulating partition is set between the winding and the iron core to further enhance the insulation performance. These insulation structures can withstand high voltage shocks, effectively prevent insulation breakdown between the primary and secondary sides, and ensure the reliability and durability of electrical isolation.

The advantages brought by the electrical isolation characteristics are significant. On the one hand, it can block the propagation path of common-mode interference current, prevent interference signals such as harmonics and surges in the power grid from affecting the normal operation of secondary-side equipment through circuit conduction, and provide pure and stable power supply for the load. On the other hand, when equipment failure occurs, since the circuits on both sides are isolated from each other, the fault current will not spread to the other side, effectively preventing the fault from expanding and reducing the difficulty and cost of maintenance. In addition, electrical isolation also provides safety protection for operators. Even if leakage occurs in the secondary-side equipment, it cannot form an effective current loop with the earth, greatly reducing the risk of electric shock.

To ensure the long-term stability of isolation performance, the transformer undergoes strict quality control during the manufacturing process. From the selection of aluminum wire, the winding accuracy of the winding, to the performance testing of the insulation material, each link follows strict standards. The finished product must undergo multiple electrical performance tests such as power frequency withstand voltage test and partial discharge test. Only products that fully meet the design requirements can be put into use. In actual operation, regular monitoring of the insulation resistance, winding DC resistance and other parameters of the transformer can timely detect potential insulation aging or performance degradation problems, ensuring that the electrical isolation function is always in the best condition.

350 KVA 400V to 140V aluminum wire three-phase isolation transformer achieves efficient and reliable electrical isolation between input and output circuits with scientific and reasonable winding design, exquisite manufacturing technology and strict quality control. It plays an irreplaceable role in many fields such as industrial production and power transmission, laying a solid foundation for the safe and stable operation of modern power systems.

Contact Us