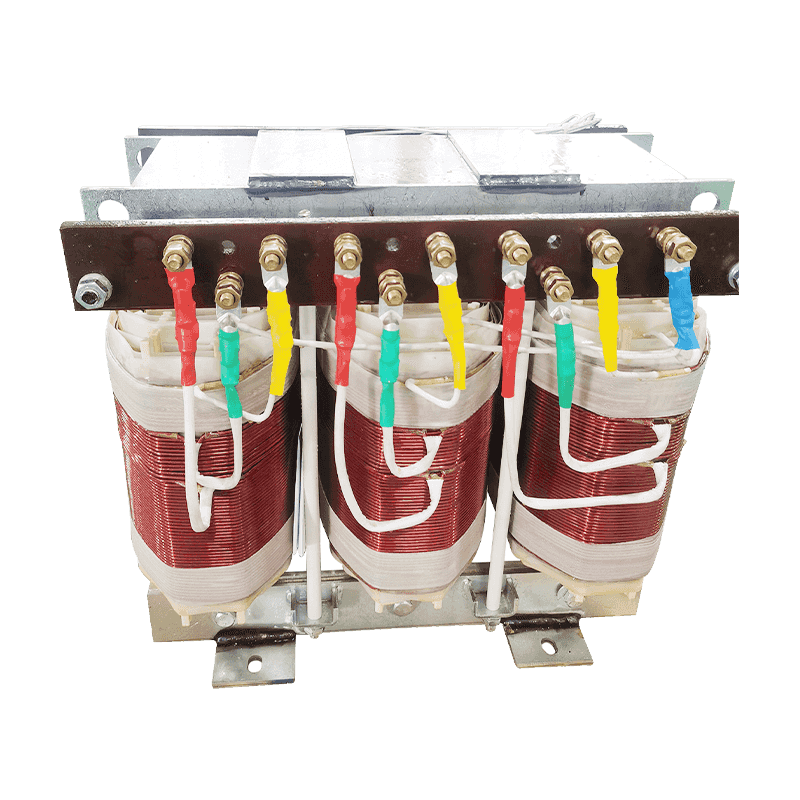

350 KVA 400V to 140V Al wire 3PH isolation transformer

Cat:Three Phase transformer

Three-phase isolation transformer series products are widely used in industrial and mining enterprises, power plants, airports, high-rise buildings, s...

See Details

In the power transmission and distribution system, the 35KVA 208V to 380V aluminum wire three-phase autotransformer provides an efficient solution for voltage conversion needs with its unique winding structure design and performance advantages. Its core secret lies in the key feature that the primary and secondary windings share the same set of coils.

Compared with traditional ordinary transformers, the winding connection method of the 35KVA 208V to 380V aluminum wire three-phase autotransformer breaks the convention. When the AC power supply is connected to the primary winding, the current flows in the common coil, and according to the law of electromagnetic induction, an alternating magnetic field is generated in the coil. As a winding material, aluminum wire can efficiently conduct current due to its good conductivity and relatively low cost, which enables the alternating magnetic field to be quickly established and operated stably. In this common winding, different turns have different functions. One part is used as a common winding, participating in both the primary and secondary circuits, and the other part acts as a series winding.

During the voltage conversion process, the realization of voltage boost from 208V to 380V depends on a cleverly designed turns ratio. The external voltage is applied to a specific part of the winding turns, and the series winding and the common winding work together to achieve voltage boost through electromagnetic induction. Due to the close electromagnetic coupling between the primary and secondary windings, the energy transfer efficiency is greatly improved. This close coupling reduces magnetic leakage and energy loss, allowing the transformer to maintain a high efficiency during voltage conversion.

In a three-phase system, three such shared windings work together in a specific connection method to ensure stable conversion and balanced output of three-phase electricity. Its winding layout has been carefully designed, fully considering the phase relationship and electromagnetic characteristics of the three-phase current, ensuring that the voltage of each phase remains stable during the conversion process, and meeting the strict requirements of three-phase electrical equipment for power quality.

This winding sharing design brings significant advantages to the 35KVA 208V to 380V aluminum wire three-phase autotransformer. Structurally, due to the reuse of windings, compared with ordinary three-phase transformers, it does not require independent primary and secondary windings, making the overall structure more compact and occupying less space, which is of great application value in the installation environment of power equipment with limited space. In terms of material use, the amount of winding wire is reduced, which not only reduces the cost of raw materials, but also reduces the overall weight of the transformer, making it more convenient during transportation and installation.

In actual application scenarios, the transformer shows strong applicability due to its characteristics. In the industrial field, for some equipment with strict voltage requirements, such as precision machining machine tools, automated production line equipment, etc., it can accurately boost the input 208V voltage to 380V to ensure stable operation of the equipment and reduce equipment failures and losses caused by voltage mismatch. In commercial buildings and public facilities, when the power system needs to adjust the voltage to meet the electricity demand in different areas, it can play a flexible role to improve the stability and reliability of power transmission.

From the perspective of manufacturing process, in order to ensure the performance of the winding common structure, strict requirements are placed on the winding process, insulation treatment and assembly accuracy of each component of the aluminum wire during the production process. Precision winding technology ensures accurate winding turns to achieve accurate voltage conversion; good insulation treatment prevents short circuits between windings and ensures safe operation of transformers; high-precision assembly ensures the coordinated working performance of three-phase windings and maintains balanced output of three-phase voltage.

The 35KVA 208V to 380V aluminum wire three-phase autotransformer achieves efficient and stable voltage conversion through the unique design of the primary and secondary windings sharing the same set of coils, combined with the characteristics of aluminum wire materials and the three-phase system layout, and plays an indispensable role in many power application scenarios.

Contact Us