In modern electrical systems, transformers play a crucial role in ensuring efficient power distribution, voltage regulation, and energy stability. Among the various transformer types available, the three-phase R-type transformer has gained significant attention due to its unique design and performance advantages. Unlike traditional laminated-core transformers, the R-type (toroidal) construction offers superior efficiency, reduced electromagnetic interference, and a more compact footprint—making it an ideal choice for industrial, renewable energy, and high-precision applications.

Who Needs Three-Phase R-Type Transformers? Key Industries and Use Cases

The adoption of three-phase R-type transformers is driven by industries that demand high energy efficiency, minimal electrical losses, and reliable performance under continuous operation. These transformers are particularly well-suited for environments where space constraints, noise sensitivity, and power quality are critical concerns.

Industrial Manufacturing

In manufacturing plants, heavy machinery and motor-driven systems require stable voltage supply with minimal harmonic distortion. The three-phase R-type transformer excels in such settings due to its low no-load losses and reduced heat generation, which contribute to longer operational lifespans. Additionally, their toroidal design minimizes electromagnetic interference (EMI), preventing disruptions to sensitive control systems.

Renewable Energy Systems

With the increasing integration of solar and wind power into electrical grids, three-phase R-type transformers are frequently used in inverter-based systems. Their ability to handle fluctuating loads while maintaining high efficiency makes them ideal for renewable energy applications. Furthermore, their compact design allows for easier installation in distributed generation setups, where space optimization is essential.

Data Centers and Critical Infrastructure

Data centers rely on uninterrupted power supplies (UPS) and clean voltage regulation to protect sensitive IT equipment. The low acoustic noise and high efficiency of R-type transformers make them suitable for noise-sensitive environments. Their robust construction also ensures reliability in 24/7 operations, reducing the risk of downtime.

Commercial and Smart Grid Applications

As smart grids evolve, the demand for transformers that support bidirectional power flow and dynamic load management grows. Three-phase R-type transformers align well with these requirements due to their high efficiency across varying load conditions, making them a future-proof choice for modern grid infrastructure.

What Are the Defining Features of Three-Phase R-Type Transformers?

The three-phase R-type transformer distinguishes itself from conventional transformers through several key structural and performance characteristics. Understanding these features helps users evaluate whether they are the right fit for specific applications.

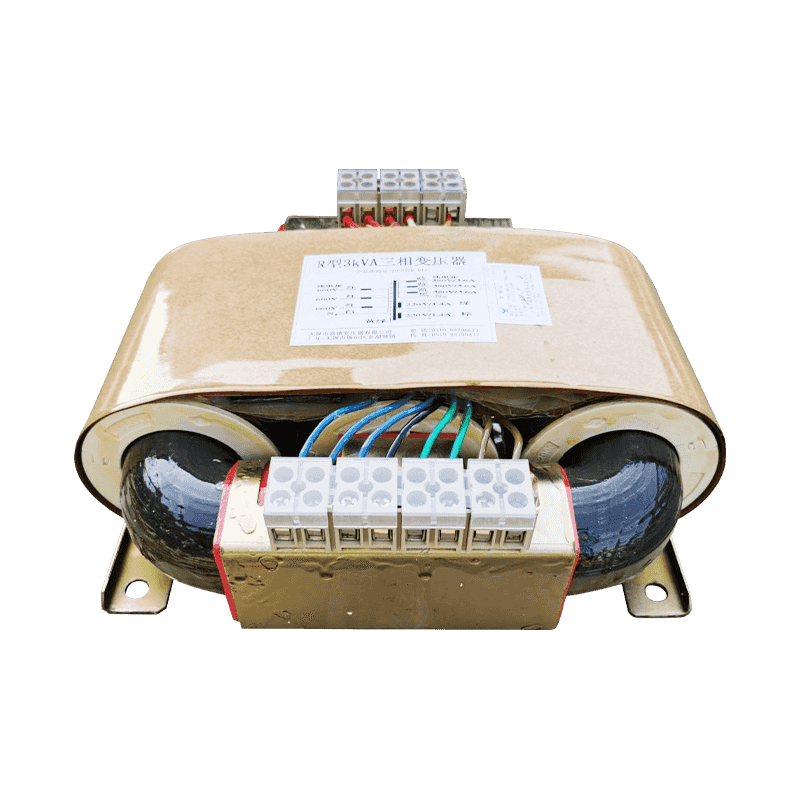

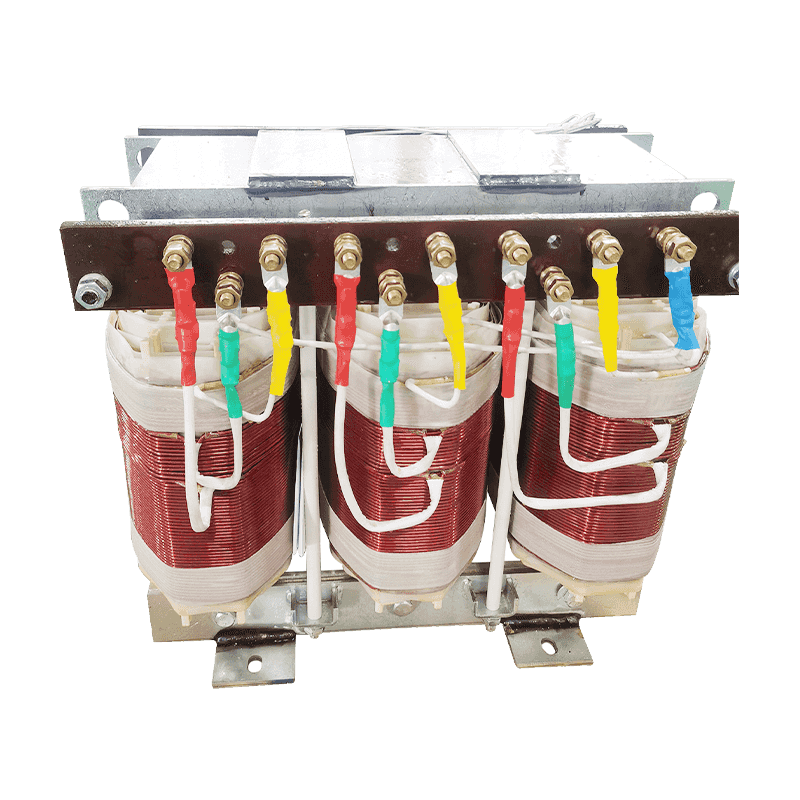

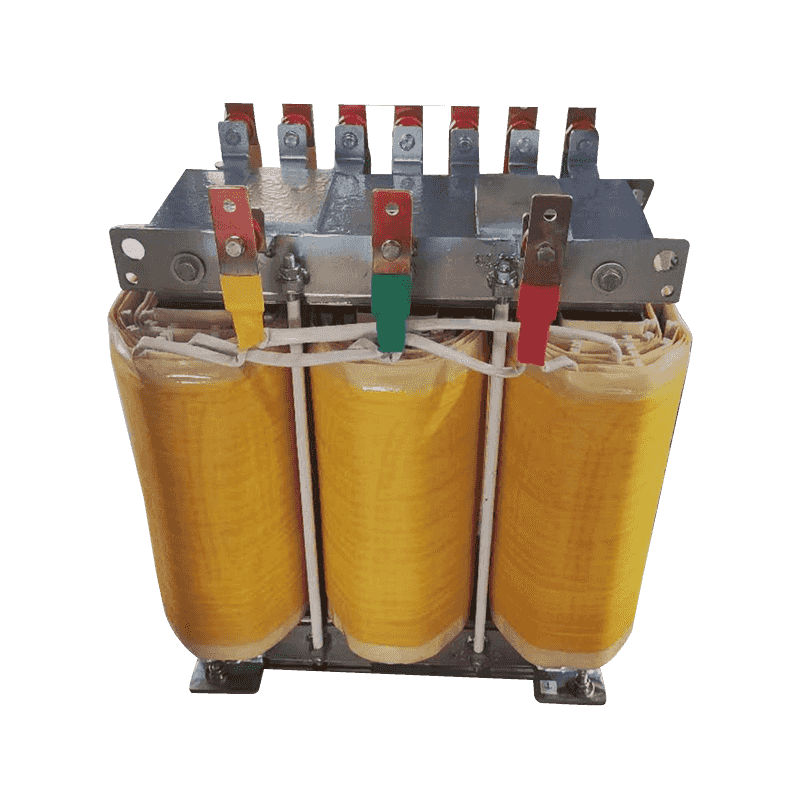

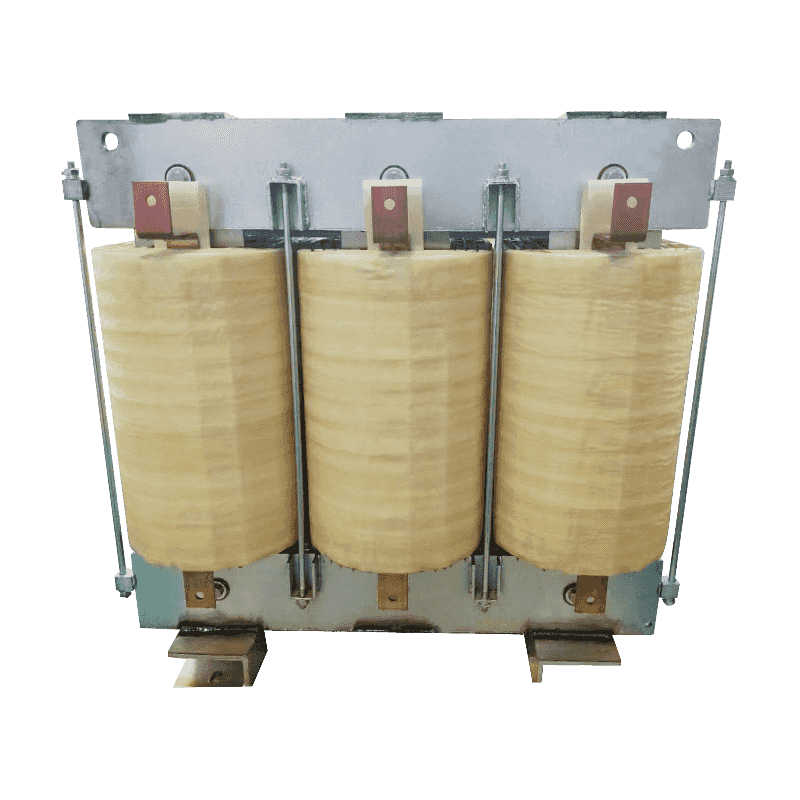

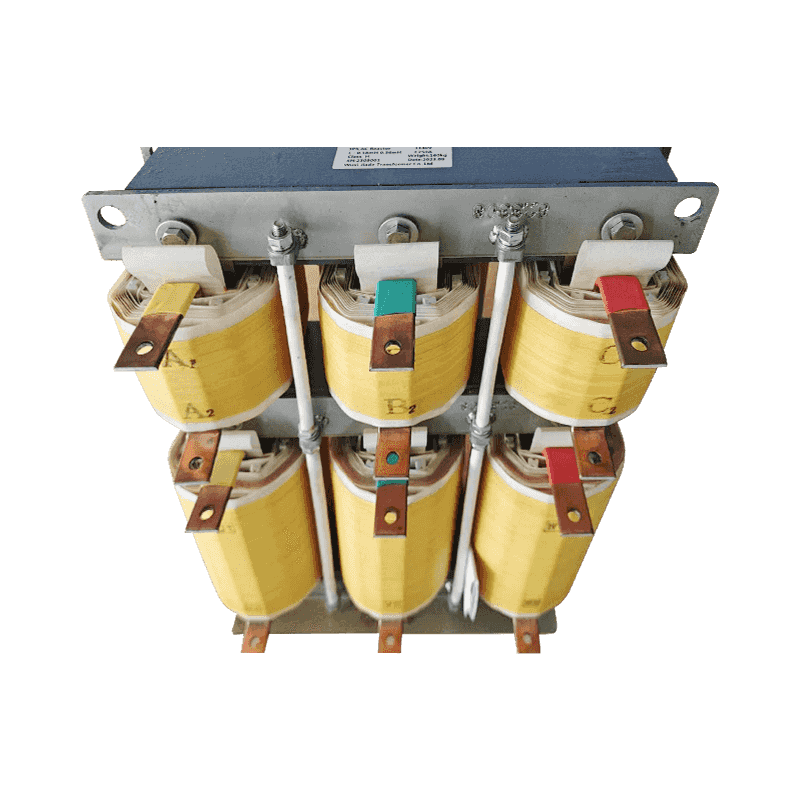

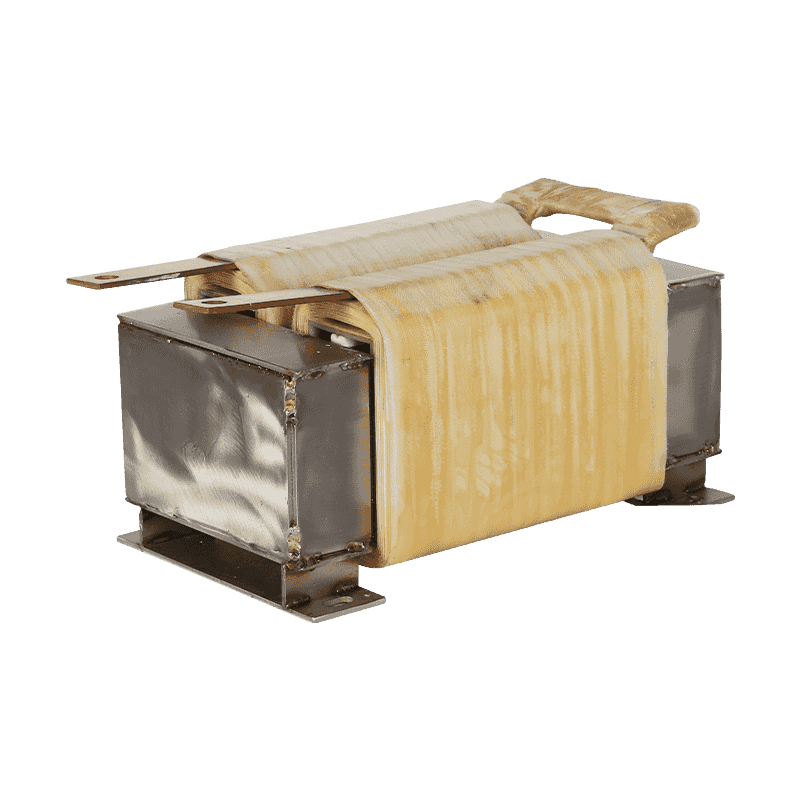

Toroidal Core Design

Unlike traditional EI-core or shell-type transformers, the R-type transformer employs a toroidal (ring-shaped) core made from grain-oriented silicon steel or amorphous metal. This design ensures a continuous magnetic path, significantly reducing core losses and improving efficiency. The absence of air gaps also minimizes vibration and audible noise, making these transformers suitable for noise-sensitive installations.

High Efficiency and Low Losses

One of the most compelling advantages of three-phase R-type transformers is their energy efficiency. Due to their optimized magnetic flux distribution, they exhibit lower no-load losses compared to laminated-core transformers. This efficiency translates into reduced operational costs, particularly in applications where transformers run continuously.

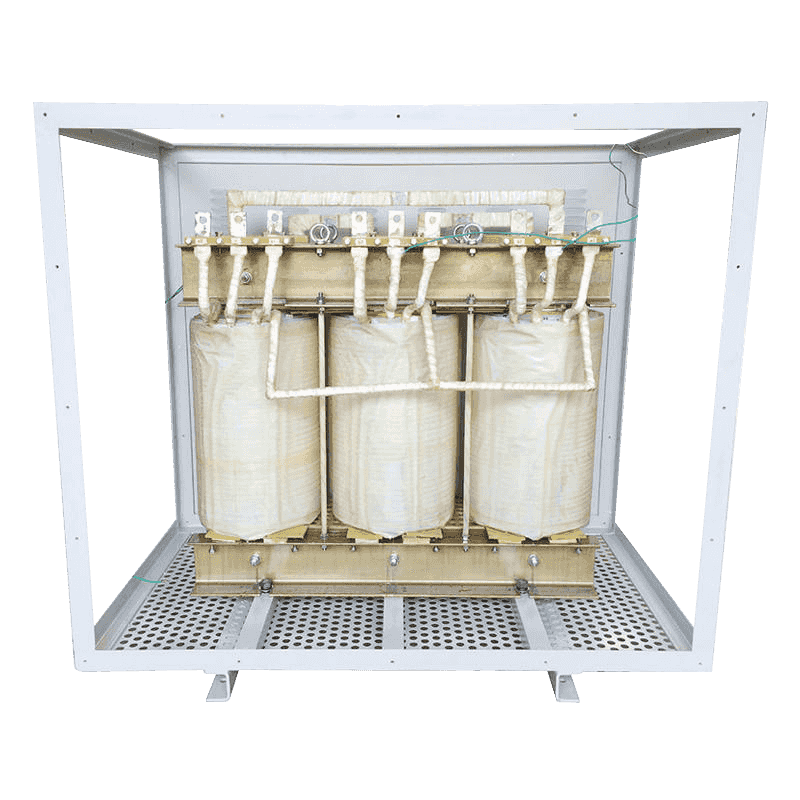

Thermal Performance and Cooling Efficiency

The toroidal design allows for better heat dissipation, as the windings are evenly distributed around the core. This results in lower operating temperatures, which enhances longevity and reduces the need for additional cooling systems. In high-ambient-temperature environments, this thermal stability is a decisive factor in transformer selection.

Compact and Lightweight Construction

The absence of bulky laminated cores means R-type transformers are significantly more compact and lighter than their counterparts. This makes them easier to install in space-constrained environments, such as modular power distribution units or renewable energy enclosures.

| Feature |

Three-Phase R-Type Transformer |

Traditional EI-Core Transformer |

| Core Material |

Toroidal silicon steel/amorphous metal |

Laminated steel |

| Efficiency |

High (up to 98%) |

Moderate (90-95%) |

| Noise Level |

Low (<40 dB) |

Moderate (50-60 dB) |

| Weight & Size |

Compact and lightweight |

Bulky and heavier |

| Thermal Performance |

Excellent heat dissipation |

Requires additional cooling |

How Do Three-Phase R-Type Transformers Solve Common Power Challenges?

Electrical systems face numerous challenges, including voltage instability, harmonic distortion, and energy losses. The three-phase R-type transformer addresses these issues effectively, making it a preferred choice for demanding applications.

Voltage Stability and Flicker Mitigation

Industrial facilities often experience voltage sags and surges due to fluctuating loads. The R-type transformer’s superior magnetic coupling ensures stable output voltage, reducing the risk of equipment malfunctions. This is particularly beneficial in manufacturing plants where voltage dips can disrupt production lines.

Harmonic Suppression for Clean Power

Non-linear loads, such as variable frequency drives (VFDs) and rectifiers, introduce harmonics into the power system. The toroidal core design inherently mitigates harmonic distortion, ensuring cleaner power delivery. This is crucial for applications involving sensitive electronics, medical equipment, and precision instrumentation.

Enhanced Durability in Harsh Environments

Many industrial and outdoor installations expose transformers to moisture, dust, and temperature extremes. The three-phase R-type transformer’s sealed and robust construction provides better resistance to environmental factors, ensuring reliable performance even in challenging conditions.

What Should Buyers Evaluate When Selecting an R-Type Transformer?

Choosing the right three-phase R-type transformer requires careful consideration of technical specifications, operational requirements, and long-term value. Below are the key factors that influence procurement decisions.

Load Capacity and Voltage Ratings

Users must match the transformer’s kVA rating and input/output voltage specifications with their system requirements. Overloading a transformer can lead to premature failure, while underutilization results in unnecessary costs.

Energy Efficiency Standards

Compliance with international standards (e.g., IEC, DOE, or ENERGY STAR) ensures the transformer meets minimum efficiency benchmarks. Higher-efficiency models may have a higher upfront cost but offer significant energy savings over time.

Customization and Scalability

Some applications require customized winding configurations or special insulation materials. Buyers should assess whether the manufacturer offers flexible design options to meet specific needs.

Total Cost of Ownership (TCO)

While three-phase R-type transformers may have a higher initial cost than conventional models, their lower energy losses and maintenance requirements often justify the investment. A lifecycle cost analysis helps determine the most economical choice.

The three-phase R-type transformer represents a significant advancement in power distribution technology, offering superior efficiency, compact design, and enhanced reliability. Its applications span critical industries—from renewable energy to industrial automation—where energy savings and operational stability are paramount.

When selecting a transformer, buyers must weigh technical specifications against long-term operational benefits. By opting for an R-type transformer, businesses can achieve not only immediate performance improvements but also sustained cost savings and future-proof power solutions. As electrical systems continue to evolve, the demand for high-efficiency, low-noise transformers will only grow, solidifying the three-phase R-type transformer’s role in modern energy infrastructure.

Eng

Eng  Español

Español

Contact Us