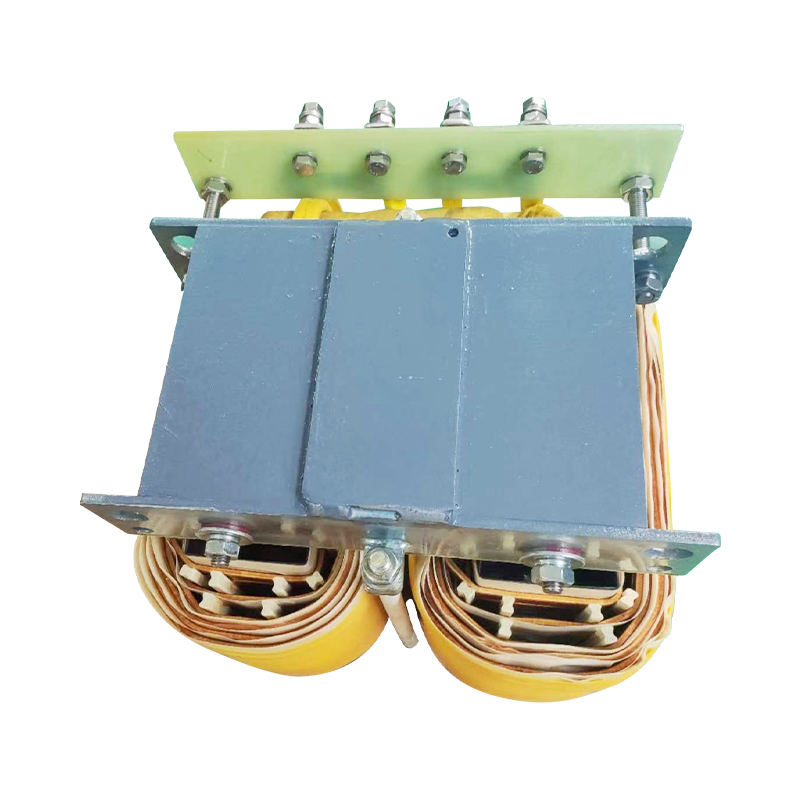

30KVA AL wire 230V to 480V 3PH Dry-type Transformer

Cat:Three Phase transformer

A three-phase transformer is a type of power transformer used to convert voltage from one three-phase circuit to another. They are widely used in powe...

See Details

As a special type of power transformer, 3PH dry-type transformer undertakes the key task of converting the voltage of one three-phase circuit into the voltage of another three-phase circuit. It is widely used in power transmission, distribution and many industrial and civil fields.

Clever Application of Electromagnetic Induction

The operation of three-phase transformer is based on the principle of electromagnetic induction. When the three-phase AC power supply is connected to the primary winding of the transformer, the alternating current passes through the primary winding, and according to Ampere's law, an alternating magnetic field is generated around it. Since the transformer uses a high-permeability iron core, this alternating magnetic field is almost entirely concentrated and guided in the iron core. As a good conductor of magnetism, the iron core efficiently transfers the magnetic field to the secondary winding. According to Faraday's law of electromagnetic induction, when the changing magnetic field passes through the secondary winding, an electromotive force is induced in the secondary winding, thereby generating an output voltage different from the primary winding voltage. By accurately designing the turns ratio of the primary winding and the secondary winding, the required voltage conversion can be achieved.

Cooperative Operation of Each Part

The three-phase transformer is mainly composed of two parts: the iron core and the winding. The core is usually made of high-permeability silicon steel sheets stacked together. Silicon steel sheets have low hysteresis loss and eddy current loss, which can effectively concentrate and guide the magnetic field and reduce the loss of energy during magnetic transmission. The winding is the key component of the transformer to achieve power conversion. It is divided into primary winding and secondary winding. Each winding is connected to each phase of the three-phase current of the power supply. The winding is generally made of materials with good conductivity, and copper and aluminum are common. The windings are magnetically coupled to each other on the core, and the power is transferred from the primary side to the secondary side through electromagnetic induction. The transformer is also equipped with insulating materials to isolate the windings and the windings from the core to ensure that the current flows along the predetermined path, prevent leakage, and ensure the safe operation of the transformer.

Advantages of aluminum wire in three-phase transformers

In the selection of winding materials for 3PH dry-type transformers, aluminum wire has unique advantages. Low cost is a significant feature of aluminum wire. Compared with copper wire, using aluminum wire as winding material in transformers of the same power can effectively reduce production costs, which makes aluminum wire three-phase transformers more competitive in price. For large-scale applications and projects that are more cost-sensitive, the economic advantage is particularly prominent. The density of aluminum is lower than that of copper, which makes transformers with aluminum wire windings lighter. The lighter weight not only reduces transportation costs, but also makes installation more convenient, reducing the manpower and material investment required for installation. It is particularly suitable for some places that require equipment weight, such as power supporting facilities in high-rise buildings.

Wide coverage of various industries

3PH dry-type transformers are widely used in many fields due to their efficient and reliable voltage conversion performance. In the industrial field, whether it is a production line in a large factory or a precision instrument manufacturing workshop, a stable voltage that meets the requirements of the equipment is required. The three-phase transformer can accurately convert the grid voltage into the voltage level required by various industrial equipment to ensure the normal operation of the equipment and improve production efficiency. In commercial buildings, such as shopping malls and office buildings, three-phase transformers play an indispensable role in meeting the different voltage requirements of various electrical equipment such as lighting, air conditioning, and elevators, ensuring stable and reliable power supply in commercial places. In the field of medical and health care, various types of precision medical equipment in hospitals, such as magnetic resonance imaging devices and computer tomography equipment, have extremely high requirements for power supply stability and voltage accuracy. Three-phase transformers can provide these devices with pure and stable power to ensure the smooth progress of medical diagnosis and treatment. In transportation, communications, education and other industries, the transformer also undertakes important power conversion tasks, providing solid power support for the development of various industries.

Contact Us